JFE India offers a proven, proprietary stoker-based grate combustion technology based on its license arrangement with our parent company JFE Engineering Corporation Japan and group company Standardkessel Baumgarte (SBG), Germany (JFE group company). The grate system have an air-cooled or water cooled variant which are selected based on waste characteristics.

The grate bars are made in high temperature and erosion resistant special alloy steel to ensure a long lifetime. The airflow and movement of the grate bars are carefully regulated by an “Automatic combustion control” system to maximize complete combustion of incoming feed. Our furnace is designed to effect a high turbulence for lowering the emissions at the generation point itself. We achieve high efficacy of drying, ignition and combustion of waste.

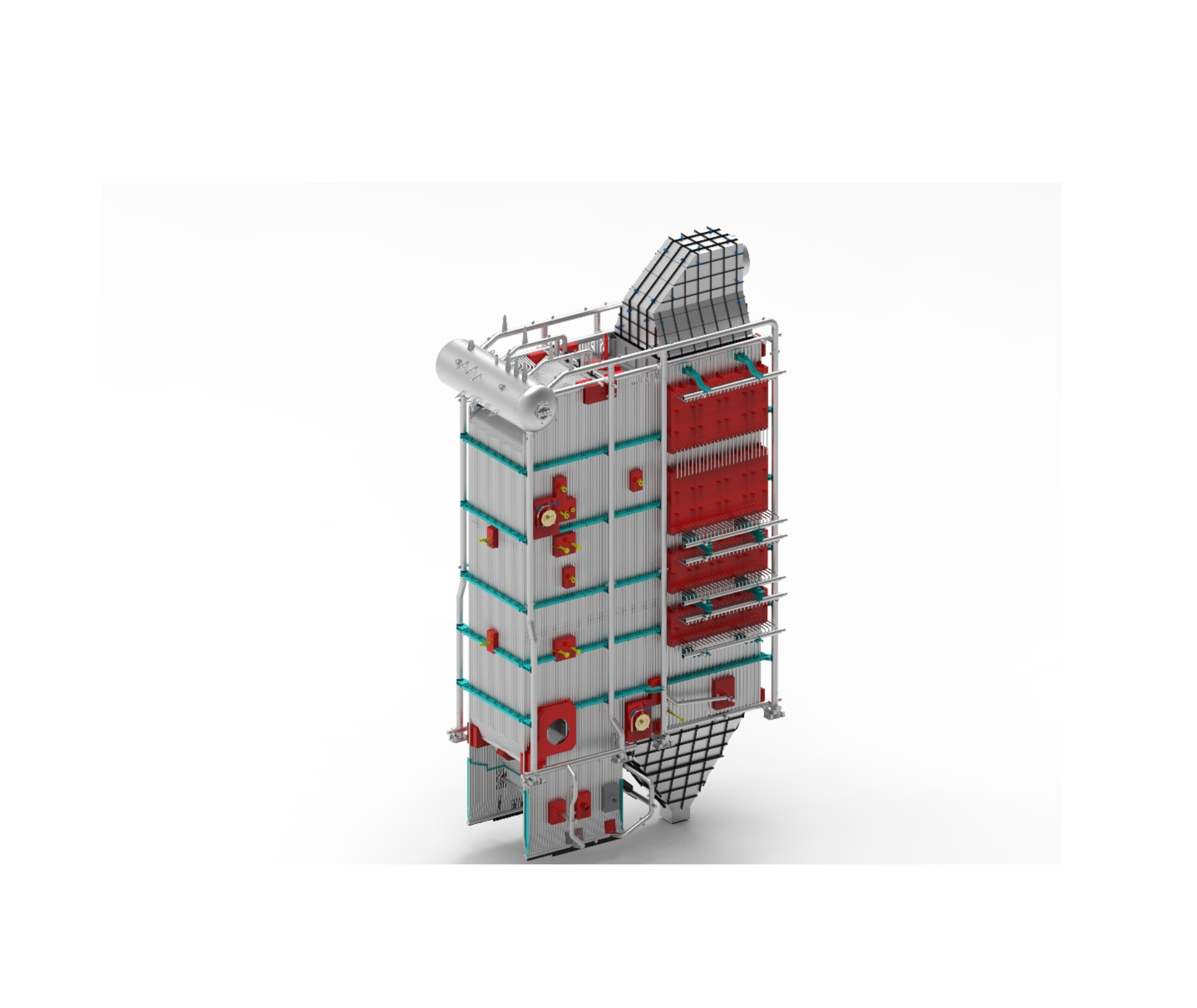

JFE India can offer either vertical or tail end configuration of Boiler as required to suit the project specifications. The Boiler system receives hot flue gases from the furnace and generates superheated high pressure steam which in turn is supplied to steam turbine for power generation.

The superheated steam parameters are optimally selected to enhance boiler life and its efficiency. In addition to steam generation, the purpose of boiler is also to cool down the Flue Gas to a condition which is suitable for air pollution control in downstream stage.

The Flue Gas treatment system offered by JFE India meets a range of statutory emission norms including but not limited to SWM 2016, EURO 2010 etc.

The Flue gas treatment aims to reduce hazardous gas contents (HCl, SOx, Nox) and carcinogenic emissions (Dioxins & Furans) generated by incineration of wide range of waste. In SNCR type De-NOx system, urea water is injected into the furnace at proper location to reduce the NOx generation. Use of SNCR shall be dependent on actual NOx and local regulations.

1968 - till date 50+ years ( group experience )

Municipal / Industrial / Mixed/RDF/SRF Can handle variety of waste

Concept to commissioning Can offer EP/EPC

Suitable for requirement

1100 - 5000 Kcal/Kg Experience of handling wide range of CV

Air cooled / Water cooled Grate suitable to waste characteristics

300 - 1100 TPD per line Solution customized to the need

Vertical / Tail end Depending upon footprint

Dry / Semi Dry Optimum for local emission norms

© 2024 JFE Engineering India Private Limited